CNC Turning Center

Precision CNC turning for small to large batch production Facing, boring, threading, grooving, and parting operations

Our Core Services

From fabrication to automation – we do it all

Precision CNC turning for small to large batch production Facing, boring, threading, grooving, and parting operations

150 Ton x 3100mm (1MM THICK TO 8 MM in various length )

Bed Size 7000×3000 Cutting Thickness 1mm to 16 mm Plasma Cutting 20 mm to 100 mm Flame Cutting

Laser Cutting Machine 3 KW Bed Size 6500 x 2000mm Max Cutting MS 16 mm & SS 12 mm

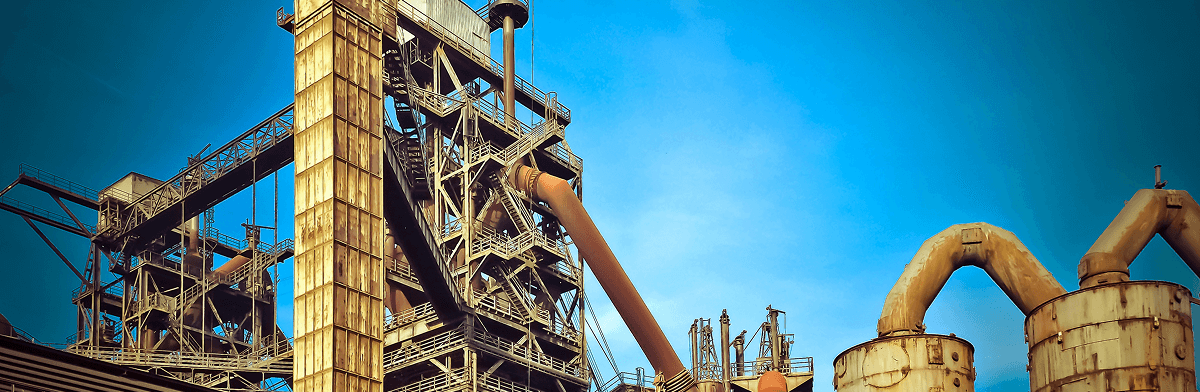

About Us

We are a trusted manufacturing and fabrication partner specializing in mechanical components, sheet-metal fabrication, CNC turning, laser & plasma cutting, and customized industrial solutions.

With a focus on quality, accuracy, and timely delivery, we support industries with durable and cost-effective products.

✔ High-precision machining

✔ Strict quality control

✔ Consistent performance

✔ On-time project completion

✔ CNC Turning & Machined Parts

✔ Laser & Plasma Cutting Job Work

✔ Conveyor Rollers & Chains

✔ Sheet Metal & Custom Fabrication

Why Choose Us.?

Frequently Asked Questions

We’re here to help with all your CNC machining, fabrication, and industrial manufacturing requirements.

Feel free to contact us for technical queries, custom job work, or quotation requests.

We provide a wide range of manufacturing and fabrication services including CNC turning and machining, laser and plasma cutting job work, sheet metal fabrication, conveyor rollers and chains, turned components, mechanical parts, and custom industrial fabrication as per drawings or samples.

Yes, we specialize in custom and job-based manufacturing. Clients can share technical drawings, specifications, or physical samples, and we manufacture components according to exact requirements. We handle prototype, small-batch, and bulk production orders.

We work with a variety of industrial materials such as Mild Steel (MS), Stainless Steel (SS), Aluminum, and Alloy Steel. Material selection is done based on application, strength, durability, and performance requirements.

Quality is maintained through careful material selection, controlled machining processes, and final inspection of finished components. Each part is checked for dimensional accuracy, surface finish, and overall workmanship to ensure reliable performance.

You can contact us by phone, email, or through the website inquiry form. Share your drawings, specifications, quantity, and material requirements, and our team will review the details and provide a competitive quotation with estimated delivery timelines.